Reliable and robust

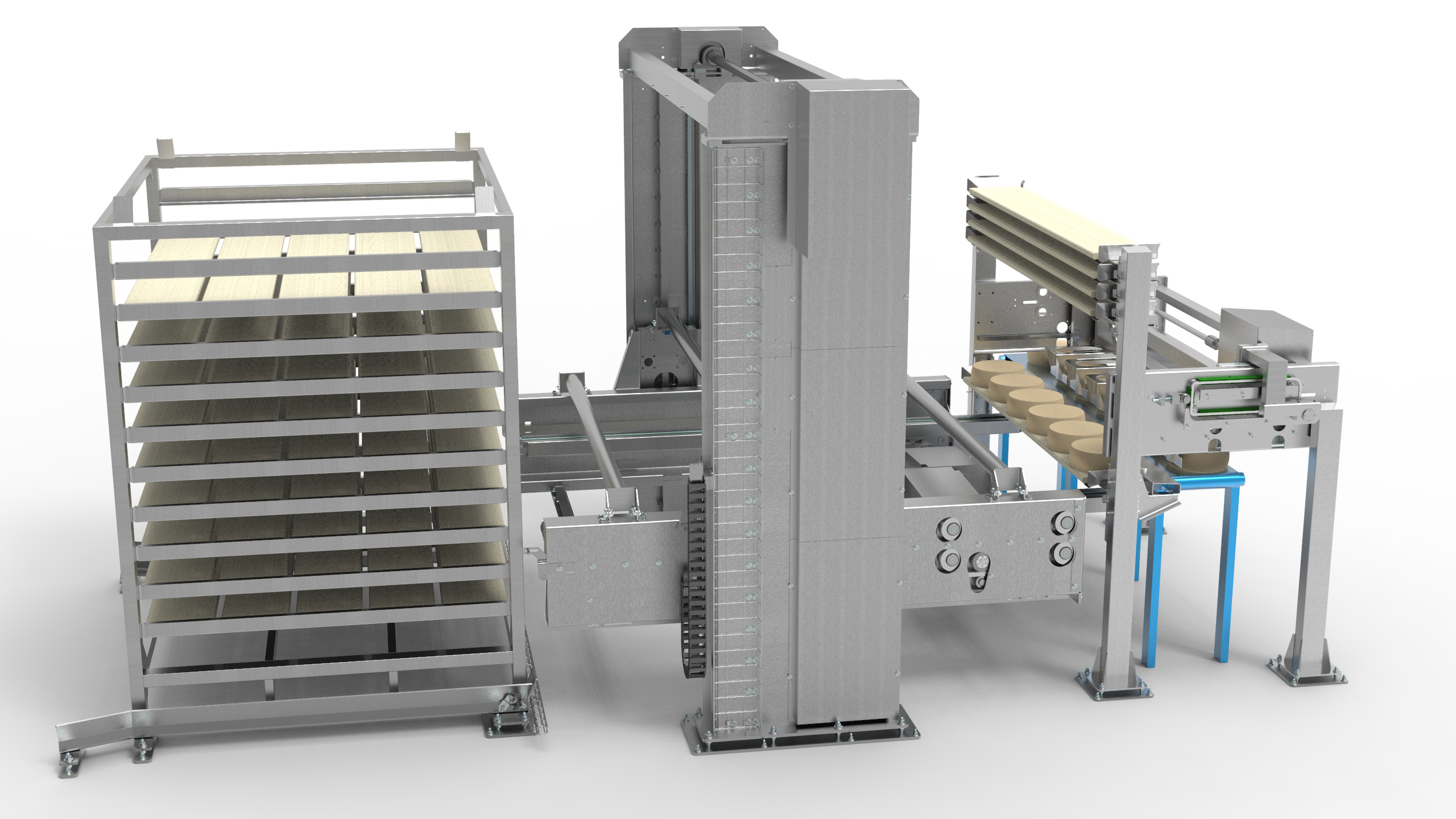

The cheese requiring further care is transported in the transport racks. The KAESARO board destacker takes the boards from the transport racks, bringing them to subsequent processing, whether cheese care or board removal.

The board destacker removes each tier of the transport rack effortlessly, readying the cheese loaves requiring further care for quick subsequent processing.

The board destacker is manufactured, assembled and commissioned in Diepoldsau, Switzerland by KAESARO. The software is integrated into the existing system or new system.

Time-saving and low-maintenance

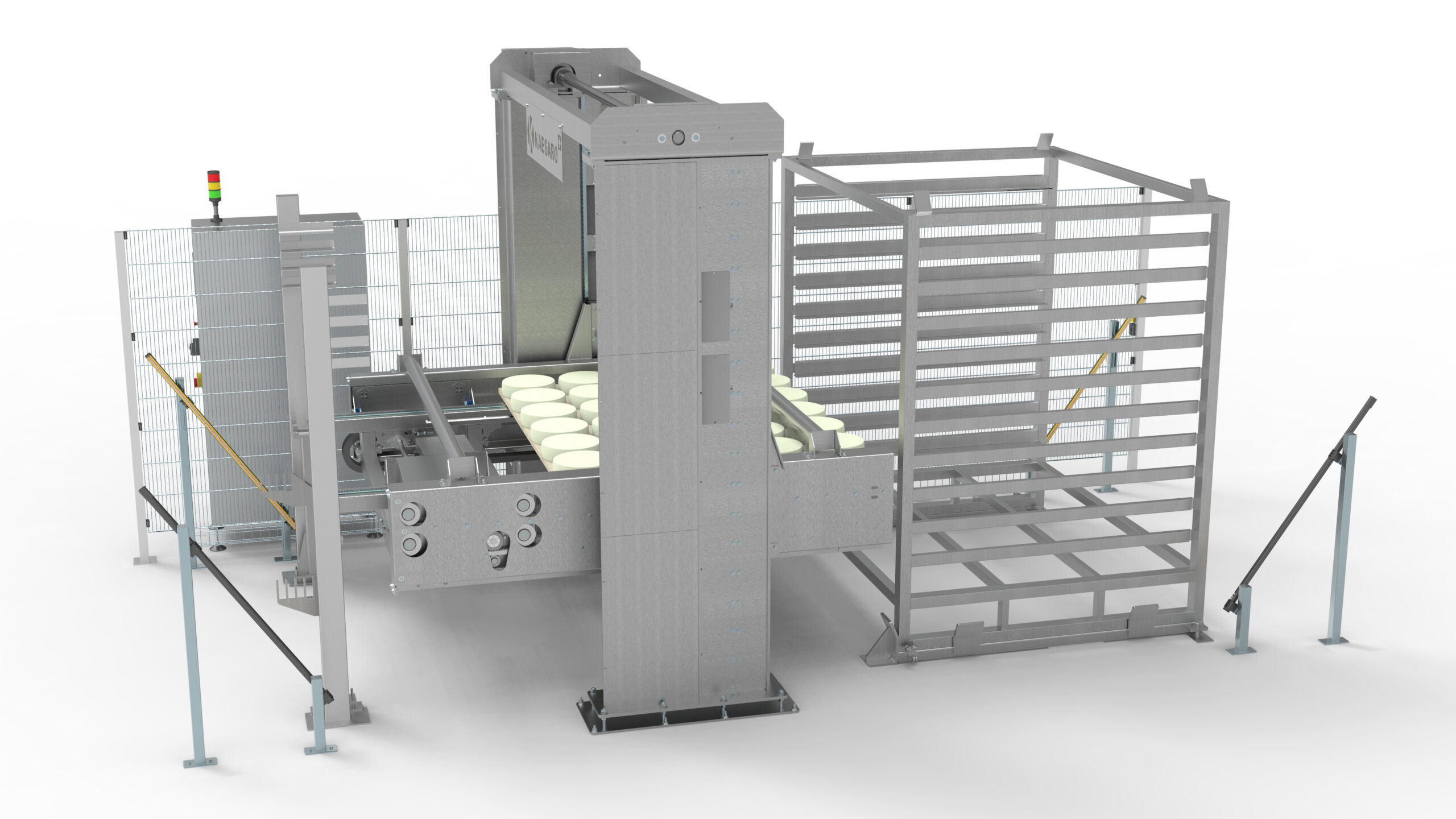

After the cheese loaves, blocks or bars have been processed, the cheese must then again be put into the transport racks.

The robust KAESARO board stacker first puts an entire tier of boards together, and the boards are then inserted into the transport rack again.

The easy-to-clean KAESARO board stacker is made of high-quality chromium steel or food-safe plastics, and can be integrated into existing or new systems.

Highest performance

Highest-performance stacking and destacking of cheese maturation shelves. Up to 500 boards per hour.

Stationary operation

An optimal addition to your KAESARO care robot or other stationary systems.

Individual design

Whether lengthwise or crosswise transport rack removal. Whether round or square-shaped cheese, the cheese stacking and destacking robot is tailored to your requirements.